The Side Stream system - HYCHLOR

HYCHLOR (ECS-Hychlor™ System)

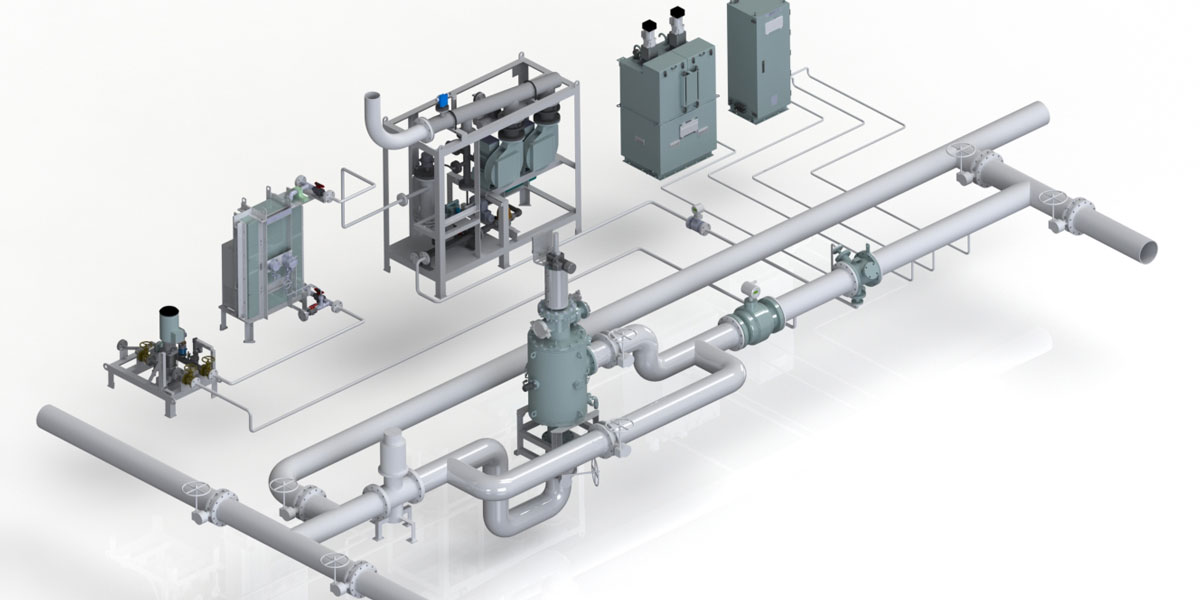

The Techcross Side Stream System, works in a different configuration. For very large vessels there might be challenges in building a full flow pipe system for ballast water – were the flow is more than 12.000 M3/hour. For that use Techcross has developed the HYCHLOR (ECS-HYCHLOR™ System) which is ballast water cleaning system using indirect electrolysis technology. This method requires however a filter, but will still be an efficient one-way cleaning, which will not requiring a second ballast water cleaning at discharge.

ECS-HYCHLOR™ System

HYCHLOR (ECS-HYCHLOR™ System) is a BMWS using indirect electrolysis technology. Techcross has enabled high efficiency for its proprietary electrodes; to respond to various customer needs, the company developed HYCHLOR, supported by another electrolysis method. HYCHLOR may be a good alternative for customers with a system with pipes that cannot directly host an electrolysis chamber.

HYCHLOR is composed of filter units, indirect electrolysis units, neutralizer, and other devices. Using the AFU installed in the main pipes, the system removes sediments and microorganisms over 50㎛. Then, only 1% of the sea water taken into the ship is sent to the indirect electrolysis unit to generate high-concentration TRO, which is then sent back to the main pipes. The water is diluted to maximum TRO concentration of 5.0mg/L, with the goal of disinfecting remaining microorganisms. During deballasting, the later bypasses AFU, only neutralizing the remaining TRO to be sent outside of the ship.

AFU (Auto Filter Unit)

1 of 9FMU (Flow Meter Unit)

2 of 9CSU (Conductivity Sensor Unit)

3 of 9PMU (Pump Module Unit)

4 of 9HGU (Hypochlorite Generation Unit)

5 of 9DMU (Degas Module Unit)

6 of 9SMU (Static Mixer Unit)

7 of 9ANU (Auto Neutralization Unit)

8 of 9TSU (TRO Sensor Unit

9 of 9Techcross Engine Room Solution (ERS) saves 200-250.000 Usd per vessel/retrofit for deep well tankers

Avoid the cost and loss of free deck space following the installation of a deckhouse. Avoid the extra BWTS unit for APT. Avoid pressure drop and extended operation time. Avoid problems in electronic equipment installed in a hot damp deck house. Call us to hear if the Engine Room Solution (ERS) is a possibility for your vessel – before you decide for a deck house.

Be prepared for a 900% increase in activities on the retrofit market!

Contact EUMT Techcross today to secure your positions